Study on the influence of structure design and usage method on the performance of insulin pen needles

Liu Yangzhi, Xin Lin, Yan Shiju, Song Chengli

School of Health Science and Engineering, University of Shanghai for Science and Technology, Shanghai 200093, China

Corresponding author: Song Chengli, Email: csong@usst.edu.cn

【Abstract】Objective The effects of various parameters on the performance of insulin pen needles during use were studied. Method The variables involved in the insulin injection process were divided into two parts:structural design and use method. The key parameters such as puncture force, penetration depth and tilt resistance of 26 needles were tested by using tensile testing machine, high-speed camera and other equipment. Results In the structural design part, the shape and size of the contact surface have a significant effect on the penetration depth, deformation, damage and anti-tilt performance. The penetration depth of the large contact surface needle is more stable, the deformation is less, the damage area is smaller, and the tilt resistance is greater. In the part of use method, the effect of needle insertion speed on puncture force was not statistically significant when it was greater than 100mm/min (p>0.05). The influence of the pressure on the penetration depth is significantly different due to the different structural design. Conclusions The large contact surface needle is less affected by different use methods, and it can be seen that it has better performance. The existing hexagonal and cross-shaped needle seats have stronger anti-tilting ability than the circular needle seats. Among them, the hexagonal needle seat is not easy to change with the rotation axis, and the performance is optimal. In the structural design, the size of the connection part should be reduced and the appropriate shape of the needle base should be selected. The results of this study can provide theoretical and experimental basis for the design and selection of insulin pen needles.

【Key words】Insulin pen needle; Injection needle; Piercing force; Piercing depth; Anti-tilt experiment

0 IntroductionAs a multifactorial chronic lifelong disease, diabetes can cause complications such as infection, cardiovascular and cerebrovascular diseases, microvascular and peripheral neuropathy, and kidney diseases, which are extremely harmful to health[1]. The supplement of exogenous insulin is a widely used method for the treatment of diabetes[2].According to the different ways of administration, it is divided into oral administration, inhalation administration, intraperitoneal administration and subcutaneous injection[3]. Because subcutaneous injection has the characteristics of quick effect, small wound and controllable injection volume, it stands out from the other three administration methods[4]. Products such as insulin pen syringes and insulin pen needles designed around this method have been widely used, and the geometric structure and mechanical properties of needles have also become research hotspots in the field of transdermal drug delivery.

The process of piercing the needle into the skin to inject insulin is affected by many factors. Not only the structural design of the needle will affect the injection effect, but also by different people used to the use of the method, such as the speed of the needle, the pressure and the relative shaking of the hand caused by breathing fluctuations. A variety of factors affect the patient 's pain, insulin injection depth and skin damage[5,6]. However, the current research in this field mainly focuses on the shape of the needle tip edge[7,8], the length of the needle tube[9], and the surface coating[10].There are few studies on the needle insertion speed, the shape of the needle seat[11], the penetration depth and the anti-tilt performance.

In this study, a multi-parameter mechanical measurement platform was built according to the national standard. The correlation between the needle speed and the piercing force was studied experimentally. The influence of the needle structure on the piercing depth, the damage area and the anti-tilting performance was analyzed. The design and selection of needles for insulin pens provide theoretical and experimental basis.

1Materials and methods1.1 Structure design of pen needleHuman skin is composed of 10 ~ 25μm stratum corneum, 70 ~ 120μm epidermis, 1 ~ 4mm dermis and more than 1mm subcutaneous tissue from the surface to the inside[12]. The effective intramuscular injection area is in the subcutaneous tissue layer through the dermis. Therefore, under the premise of ensuring that the injection is in the subcutaneous tissue layer, the penetration depth should be as small as possible to reduce hypoglycemia events, obtain better intramuscular injection effect[13], and reduce skin damage. This is also the reason why the length of the needle tube is usually designed to be 4-5mm and vertical injection is used[14,15]. Clinically obese patients, patients who cannot use 4mm needles due to hand shaking or other obstacles, can use 6mm or 8mm long needles for tilt injection or pinch injection.

In addition to the length difference of the needle, the structural difference of the needle cannot be ignored. According to the structural design, the needles can be divided into two types:conventional type (Fig.1A) and self-destruct type (Fig.1B). The self-destructing needle has an axially retractable needle seat, which gradually exposes the needle tube after being stressed. The needle seat triggers the mechanical self-locking structure in the shell, so that the needle seat cannot be retracted again after reset. The conventional needle does not contain a mechanical self-locking shell. According to the different sizes of its connecting parts, it can be divided into two types:small contact surface and large contact surface. Among them, in the commercially available large contact surface needles, according to the different shapes of the contact surface, it can be divided into three shapes:regular hexagon, circle and cross.

The small contact surface needle has a connecting part of about 3mm high. When the needle is pressed, the connecting part contacts the skin first. When the axial deformation exceeds the height of the connecting part, the needle holder can contact the skin surface to provide support. The connection part of the large contact surface needle is about 0.3mm high. During the pressing process, the skin can contact the needle seat after the axial deformation of about 0.3mm, and the contact area between the needle seat and the skin is large. The difference in the size of the contact surface will be reflected in many aspects such as penetration depth, skin damage and anti-tilt performance, which is a key factor in the performance difference of insulin pen needles.

Fig.1. Two types of needles

1.2 Main materials and instruments21 types of conventional needles were selected, and the specifications were 32G×4mm[16]. Five self-destruct needles were selected. The experimental equipment used in this study includes: Instron 5900 testing machine (Instron, USA), Photron FASTCAM Mini UX50 high-speed digital camera (Photron, Japan).

1.3 The use of the injection processIn the whole process of insulin pen injection of insulin, the different methods of use are mainly reflected in:1.the speed of needle insertion; 2.According to the size of the pressure; 3.Amplitude of hand shaking relative to abdomen. Among them, the needle insertion speed may change the size of the puncture force and affect the pain perception; the different pressure will make the needle tip penetration depth different, so that the depth of insulin injected into the skin is different, which will affect the curative effect. Hand shaking will increase the damage of the needle to the skin.

At the same time, in order to further measure the difference of anti-tilt ability of large contact surface needles with different shapes and sizes, the moment of inertia is used to describe their anti-tilt ability. The moment of inertia is a physical quantity used to describe the ability of the section geometry to resist torsion and torsion of the object, and the unit is m4. The greater the moment of inertia of the object, the stronger its stability. The moment of inertia can be obtained by the following formula[17] :

Where is the area element on the cross section, and x is the distance from the area element to the rotation axis.

Three different shapes can be divided into five cases according to their different rotation axes, as shown in Table 1. The coordinate axis is established with the centroid as the origin, and the moment of inertia is calculated when it rotates with the y axis as the axis, and the area infinitesimal is transformed into the product of the x axis and the y axis length infinitesimal. The moment of inertia in five cases is solved respectively, and the corresponding expressions are obtained. After measuring the actual size, the actual moment of inertia is calculated. The data show that the cross-shaped moment of inertia is greatly affected by different rotation axes (a difference of 8.7 times), and the hexagon is not easily affected by the change of the rotation axis (a difference of 1.4 times).

Table 1 Inertia moment expressions of different geometric shapes

Brand |

Shape |

Inertia moment expression |

Actual moment of inertia(m4) |

Sandstone Easydrip Plus |

|

|

2.71×10-10 |

|

|

1.94×10-10 |

BD Nano 2nd Gen

、Promisemed Verifine Plus |

|

|

9.89×10-11

、7.25×10-11 |

NovoFine Plus |

|

|

6.51×10-11 |

|

|

5.66×10-10 |

Brand |

Shape |

Inertia moment expression |

Actual moment of inertia(m4) |

Sandstone Easydrip Plus |

|

|

2.71×10-10 |

|

|

1.94×10-10 |

BD Nano 2nd Gen

、Promisemed Verifine Plus |

|

|

9.89×10-11

、7.25×10-11 |

NovoFine Plus |

|

|

6.51×10-11 |

|

|

5.66×10-10 |

When designing the experiment, the structural design factors that need to be considered mainly include: contact surface type, contact surface shape, and the use method factors mainly include:needle entry speed, pressing pressure, and hand shaking. To this end, experiments were designed to measure:1.the correlation between the insertion speed and the puncture force when the needle is inserted into the skin; 2.The deformation of different types of needles on the skin surface after penetration into the skin; 3.After the needle seat contacts the skin surface, the relationship between the pressure and the penetration depth, the needle structure and the damage area; 4.In the process of pushing medicine, the ability of the needle to resist the tilt and shaking of the hand.

1.4.1 Experiment on the influence of needle insertion speed on puncture force

According to the national standard ' Sterile Hypodermic Needles for Single Use' (GB15811-2016), an experimental platform was built[18]. A polyurethane film with a thickness of 0.4 mm and a Shore hardness of 92.3 HA was used as the tested material. The fixture was designed, and the diameter of the exposed area after clamping was 10 mm. The Instron5900 testing machine was used to clamp the needle and vertically puncture the measured material at a constant speed of 50mm/min, 100mm/min, 150mm/min, 200mm/min and 250mm/min respectively. The resistance of the needle was recorded as the puncture force. Six groups of experiments were carried out at each speed of each needle to analyze the influence of needle insertion speed on puncture force.

Because the needle tube of the self-destructing needle needs to be exposed to a certain pressure of the needle base, in order to eliminate the influence of the pressure of the needle base, the needle base of the self-destructing needle is pre-pressed and fixed, so that the needle tube is directly exposed to the outside, and the experiment is carried out. The subsequent experiments cannot eliminate the influence of the needle seat, so the self-destruct needle seat only performs the puncture force experiment.

1.4.2 Deformation experiment

The deformation of the skin is mainly divided into two types:the degree of skin subsidence when the needle is at a specified depth, and the degree of skin damage when the needle is pulled out. Therefore, it is necessary to select a simulated skin material with good visual performance and mechanical properties close to the skin. After selection and comparison, 6100 silicon gel (Shenzhen Yikai Electronics Co., Ltd.) was selected as the experimental material. The Shore hardness of several related materials was measured by TH200 Shore hardness tester (Beijing Times Zhongyi Technology Co., Ltd.). The measured data are shown in Table 2.

Table2 Shore hardness measurement results

| Material |

Shore hardness A |

| Abdomen |

0 |

| Inner side of the big arm |

5.8 |

| 6100 silica gel |

8 |

| Polyurethane membrane |

92.3 |

During the experiment, the tension and compression head of the testing machine is controlled to drop at a constant speed of 150mm/min. After reaching the given pressure value, it returns at the same speed. Considering that the purpose of this experiment is to photograph the deformation difference between the two types of needles on the material, the given pressure value is set to 4N. The entire process is recorded by a Photron FASTCAM Mini UX50 high-speed digital camera. Analyze the video data, select the key frame with the largest deformation, and analyze and compare the deformation of each needle under the same pressure.

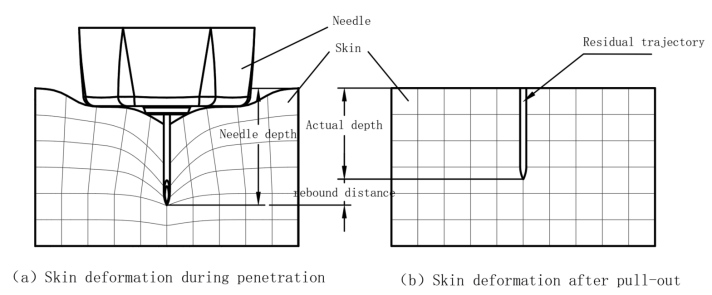

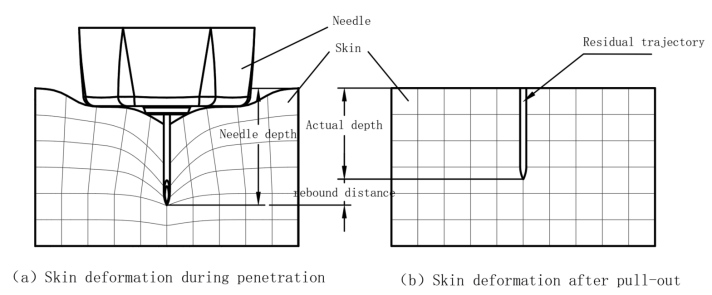

1.4.3 Piercing depth and damage experiment Because the skin has the characteristics of super-elasticity, after applying pressure to the skin surface, it will cause extrusion deformation in the lower part of the skin. The tip displacement is divided into the displacement caused by the skin being squeezed and the relative displacement of the tip in the skin. The actual penetration depth of the needle tip is the trajectory length remaining in the skin after the needle is pulled out and the skin is not stressed, as shown in Fig.2.

Fig.2. A schematic diagram of the deviation between the displacement of the needle tip and the actual penetration depth

This characteristic leads to the fact that the data obtained by the test machine cannot accurately reflect the actual penetration depth of the needle tip. To this end, two experiments were designed to measure the actual penetration depth: 1.Indirect measurement: the equal pressure force experiment was carried out on each sample, the displacement data was output, the continuous force-displacement curve was drawn, and the displacement of each needle was compared. However, this curve contains the penetration depth deviation value mentioned above. 2.Direct measurement: Pierce the measured material in the form of red ink on the needle, slowly enter and quickly exit, so that the ink remains inside the material, visually presents the actual penetration depth, obtains discrete data, and compares the actual penetration depth of each needle. At the same time, the samples after the experiment were sampled and photographed, and the damage of different needles to the material was quantified by the maximum width of the damage area.

1.4.4 Anti-tilt performance experiment

During the duration of insulin injection, on the one hand, the hand needs to hold the insulin pen, on the other hand, it needs to press the push rod of the insulin pen. The change of force is together with the abdominal ups and downs caused by respiration, resulting in the tilt of the insulin pen relative to the skin. In the case of the needle tip remaining in the human body, the tilt will cause deformation and damage to the skin, affecting the injection effect[19]. Therefore, when measuring the performance of the insulin pen needle, the resistance provided by the tilt is used as an index to evaluate the anti-tilt ability of the needle. The Instron testing machine was used in the experiment. The material was a silicon gel with a thickness of 10 mm, which was fixed on a fixture capable of tilting at a specified angle. Start the testing machine, stop the testing machine when the lower pressure is 2N, maintain the penetration depth, tilt the fixture, and collect the axial resistance of the needle at 6°, 9°, and 12°. To reflect the differences between different structural designs.

1.5 Statistical method

Statistical analysis was performed on the experimental data. One-way analysis of variance was performed using SPSS 27.0 software (IBM,USA) and LSD (Least Significant Digit) multiple comparison method. p < 0.05 was considered statistically significant.