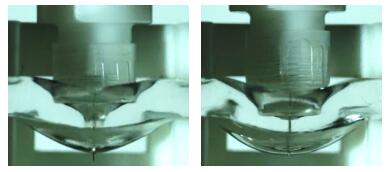

Through the frame-by-frame selection of the video taken by the high-speed camera, the deformation maps of the two types of needles under the same pressure on the 5.7mm thickness silicone gel are obtained as shown in Fig.5. The penetration depth of the needle on the small contact surface is large, and the needle tip has pierced the silica gel. The deformation of the needle joint to the material is significant, and the local stress concentration effect is obvious. The penetration depth of the needle with large contact surface is small, and the needle tip does not pierce the silica gel. The upper surface of the material is contacted in the form of a large plane, and the local stress concentration effect is not obvious.

(a)Small contact surface needle (b)Large contact surface needle

Fig.5. The deformation diagram of silicon gel produced by two types of needles

2.3 Piercing depth and damage experiment

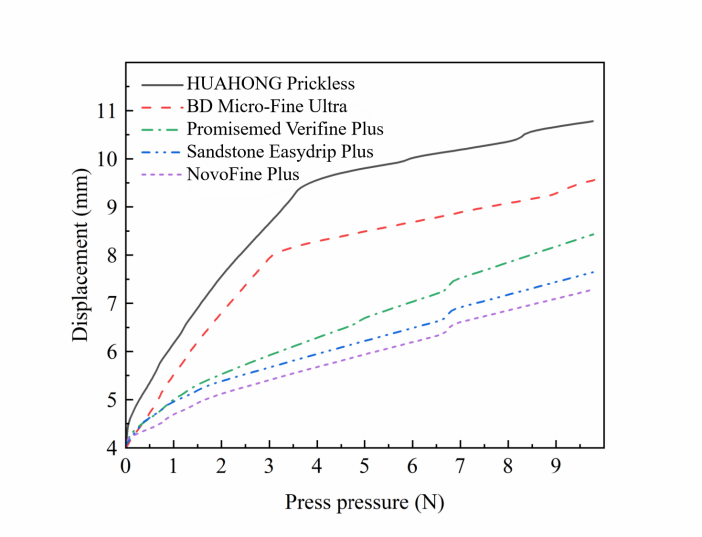

Indirect measurement:10mm thick silica gel was selected, and the pressing speed was controlled to be 150mm/min by the testing machine, and the recording was stopped when the resistance reached 10N. The pressure-displacement curve is plotted after the needle joint is contacted with the material surface, as shown in Fig.6.

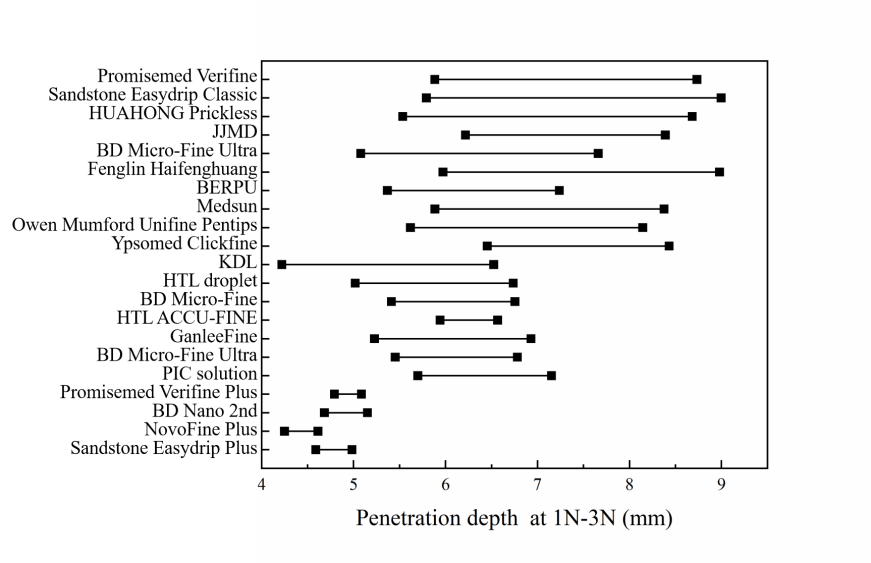

Direct measurement:Using NK-5 push-pull meter (Dongguan Sanliang Measuring Instrument Co., Ltd.), the pressure of the needle used for insulin pen was measured to be about 1N to 3N. The penetration depth and maximum damage width of each sample at pressure of 1N and 3N were obtained by residual ink. The values are shown in Table 4, and the line segment diagram is shown in Fig.7.

Fig.6. Displacement curve of piercing process

Fig.7. The penetration depth of each sample at pressure of 1N-3N

2.4 Anti-tilt performance experiment

When the downward pressure is 2N, the test machine is stopped, and the value of the axial resistance of the needle is recorded when the sample is tilted to 6°, 9° and 12°, respectively. The maximum value of each needle at 12°is filled in Table 3, and the sample data is arranged in descending order according to this value, and the diagram is drawn, as shown in Fig.8.

Fig.8. The axial resistance diagram of different angles when the pressure is 2N

1Discussion and conclusions

From the indirect measurement of the displacement curve of the testing machine and the direct measurement of the retained ink marks, it can be found that the large contact surface needle has significant advantages in controlling the penetration depth. Compared with the small contact surface needle, the large contact surface needle is more likely to control the penetration depth at about 4mm. Under the pressure of 3N, the penetration depth of Sandstone Easydrip Plus and NovoFine Plus can be controlled within 5mm, which can effectively prevent the needle from penetrating the tissue too deep and reduce the risk of intramuscular injection. The reason is that the contact area between the needle seat of the small contact surface needle and the skin is small, and the resistance to the hand is small and the skin deformation is large during the pressing injection process, resulting in a deeper penetration depth of the needle tip in the human tissue. However, due to the large contact area between the needle and the skin, the injection resistance is large and the skin deformation is small, which makes the penetration depth of the needle tip shallow.

From the experiment of tilt resistance, it can be intuitively seen that the four large contact surface needles can provide greater resistance when the hand is offset and shaken, indicating that the large contact surface needles have significant advantages in positioning stability. Its anti-inclination interference performance is better, and it is easier to maintain the vertical stability between the needle and the skin during the injection process, reducing the risk of needle bending. The reason is that according to the theory of material mechanics, the moment of inertia of the contact surface between the needle holder with large contact surface and the skin is much larger than that of the needle holder with small contact surface, which makes it easier to prevent instability caused by transverse interference force. In the large contact surface needle, the maximum anti-tilting resistance is the hexagonal needle seat rather than the cross-shaped needle seat with the largest moment of inertia in Table 1. The possible reason is that the NovoFine Plus needle seat has a high inside and low outside radian in the axial direction, which reduces the anti-tilting performance to a certain extent. The rest of the needle seat surface can be regarded as a plane, and the tilt resistance ranking is consistent with the inertia moment ranking calculated numerically in Table 1.

In this study, a number of parameters involved in the use of different types of insulin pen needles were quantified. It was found that the shape and size of the contact surface were the key factors affecting the penetration depth, deformation, damage and anti-tilt performance, while the correlation between the insertion speed and the puncture force was not statistically significant.

The needle with a large contact area with the skin has a large resistance during the pressing process, which can prevent the needle from penetrating too deep and reduce the risk of intramuscular injection. The needle with larger moment of inertia on the contact surface with the skin has better anti-lateral force interference performance, and it is easier to maintain the vertical stability between the needle and the skin during the injection process, which is convenient to maintain the insulin injection operation standard and reduce the risk of needle bending. Among the needles with large contact surface, the needle with hexagonal structure design has the best anti-tilt ability, and has less influence with the change of rotation axis, and has strong stability.

On the premise of ensuring the stability of the needle tube, the performance of the above parameters of the needle for insulin pen can be improved by optimizing the structure of the needle base and reducing the size of the connecting part. The results of this study can provide theoretical and experimental basis for the use and design of insulin pen needles.

In addition, the self-destruct needle has its unique structural design:through the movable resistance needle seat to maintain the stability of the penetration depth; the inclination angle is reduced by a longer axial length; the self-destructing structure prevents it from being mistakenly stabbed and reused. Due to the limitation of space, this paper has not done too much research on self-destruct needles, which can be used as the direction of future research.

References

[1] Sun H, Saeedi P, Karuranga S, et al. IDF Diabetes Atlas: Global, regional and country-level diabetes prevalence estimates for 2021 and projections for 2045[J]. Diabetes Research and Clinical Practice, 2022, 183: 109119. DOI:10.1016/j.diabres.2021.109119.

[2] Guyton J, Jeon M, Brooks A. Glucagon-like peptide 1 receptor agonists in type 1 diabetes mellitus[J]. American journal of health-system pharmacy: AJHP: official journal of the American Society of Health-System Pharmacists, 2019, 76(21): 1739-1748. DOI:10.1093/ajhp/zxz179.

[3] Gupta J, Felner E I, Prausnitz M R. Minimally invasive insulin delivery in subjects with type 1 diabetes using hollow microneedles[J]. Diabetes Technology & Therapeutics, 2009, 11(6): 329-337. DOI:10.1089/dia.2008.0103.

[4] Karmakar S, Bhowmik M, Laha B, et al. Recent advancements on novel approaches of insulin delivery[J]. Medicine in Novel Technology and Devices, 2023, 19: 100253. DOI:10.1016/j.medntd.2023.100253.

[5] Aronson R, Gibney M A, Oza K, et al. Insulin pen needles: effects of extra-thin wall needle technology on preference, confidence, and other patient ratings[J]. Clinical Therapeutics, 2013, 35(7): 923-933.e4. DOI:10.1016/j.clinthera.2013.05.020.

[6] Kreugel G, Keers J C, Kerstens M N, et al. Randomized trial on the influence of the length of two insulin pen needles on glycemic control and patient preference in obese patients with diabetes[J]. Diabetes Technology & Therapeutics, 2011, 13(7): 737-741. DOI:10.1089/dia.2011.0010.

[7] 崔赛辉, 朱洪旺, 潘贞, 等. 胰岛素笔用针头性能的有限元分析与实验研究 [J] . 国际生物医学工程杂志,2019,42(06): 497-502. DOI:10.3760/cma.j.issn.1673-4181.2019.06.008

Cui Saihui, Zhu Hongwang, Pan Zhen, et al. Finite element analysis and experimental study on the performance of insulin pen needles[J]. International Journal of Biomedical Engineering, 2019,42(06): 497-502. DOI:10.3760/cma.j.issn.1673-4181.2019.06.008 [in chinese]

[8] Wang Y, Li W, Han P, et al. Contributions in medical needle technologies—Geometry, mechanics, design, and manufacturing[J]. Machining Science and Technology, 2016, 20(1): 1-43. DOI:10.1080/10910344.2015.1133917.

[9] Juul K A P, Bengtsson H, Eyving B, et al. Influence of hypodermic needle dimensions on subcutaneous injection delivery--a pig study of injection deposition evaluated by CT scanning, histology, and backflow[J]. Skin research and technology: official journal of International Society for Bioengineering and the Skin (ISBS) [and] International Society for Digital Imaging of Skin (ISDIS) [and] International Society for Skin Imaging (ISSI), 2012, 18(4): 447-455. DOI:10.1111/j.1600-0846.2011.00592.x.

[10] Patel K I, Zhu L, Ren F, et al. Effect of composite coating on insertion mechanics of needle structure in soft materials[J]. Medical Engineering & Physics, 2021, 95: 104-110. DOI:10.1016/j.medengphy.2021.07.008.

[11] Rini C, Roberts B C, Morel D, et al. Evaluating the Impact of Human Factors and Pen Needle Design on Insulin Pen Injection[J]. Journal of Diabetes Science and Technology, 2019, 13(3): 533-545. DOI:10.1177/1932296819836987.

[12] 王缘, 马凤森, 王延妮, 等. 皮肤模型与微针穿刺性能评价的研究[J]. 生物化学与生物物理进展, 2022, 49(8): 1406-1421. DOI:10.16476/j.pibb.2021.0277.

Wang Yuan, Ma Fengsen, Wang Yanni, et al. Evaluation of skin model and microneedle puncture performance [J]. Advances in biochemistry and biophysics, 2022, 49 (8): 1406-1421. DOI: 10.16476/j.pibb.2021.0277 [in chinese]

[13] Sun L, Sun J, Chen B, et al. PDB25 - Effectiveness, Safety and Patients’ Subjective Feelings of Insulin Pen-Needle: A Systematic Review[J]. Value in Health, 2014, 17(7): A336. DOI:10.1016/j.jval.2014.08.647.

[14] Gibney M A, Arce C H, Byron K J, et al. Skin and subcutaneous adipose layer thickness in adults with diabetes at sites used for insulin injections: implications for needle length recommendations[J]. Current Medical Research and Opinion, 2010, 26(6): 1519-1530. DOI:10.1185/03007995.2010.481203.

[15] Berard L, Cameron B, Woo V. Pen Needle Preference in a Population of Canadians with Diabetes: Results from a Recent Patient Survey[J]. Canadian Journal of Diabetes, 2015, 39(3): 206-209. DOI:10.1016/j.jcjd.2014.09.008.

[16] Whooley S, Briskin T, Gibney M A, et al. Evaluating the User Performance and Experience with a Re-Engineered 4 mm × 32G Pen Needle: A Randomized Trial with Similar Length/Gauge Needles[J]. Diabetes Therapy: Research, Treatment and Education of Diabetes and Related Disorders, 2019, 10(2): 697-712. DOI:10.1007/s13300-019-0585-7.

[17] Lee G J. Moment of inertia of liquid in a tank[J]. International Journal of Naval Architecture and Ocean Engineering, 2014, 6(1): 132-150. DOI:10.2478/IJNAOE-2013-0168.

[18] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 一次性使用无菌注射针: GB 15811—2016[S]. 北京: 国家标准出版社, 2016. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, China National Standardization Administration. Sterile Hypodermic Needles for Single Use: GB 15811—2016 [S]. Beijing: China Standards Press, 2016. [in chinese]

[19] Beyers K C L, Rbeihat M N M, S. Vasconcelos D, et al. Preclinical evaluation of performance, safety and usability of VAX-ID, a novel intradermal injection device[J]. Vaccine, 2023, 41(31): 4609-4615. DOI:10.1016/j.vaccine.2023.06.028.

[20] Asadian A, Patel R V, Kermani M R. Dynamics of translational friction in needle-tissue interaction during needle insertion[J]. Annals of Biomedical Engineering, 2014, 42(1): 73-85. DOI:10.1007/s10439-013-0892-5.